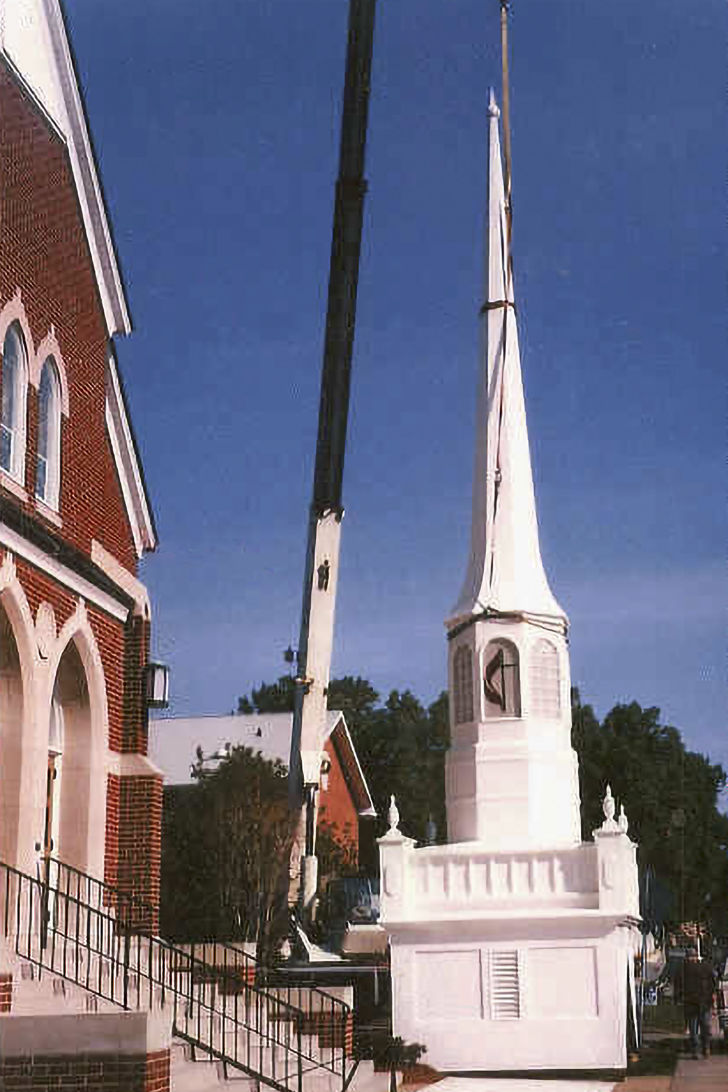

Schafer Mfg. Co.

Leaders in Fiberglass Products since 1956

Leaders in Fiberglass Products since 1956

"One Nation Under God"

551 N Main Street, Troutman, NC 28166

P.O. Box 388, Troutman, NC 28166